Full View

Ähnlech Saachen

400W LED portable UV colloid curing lamp Print head inkjet photo printer curing 395nm cob UV led lamp

111 verkaf

€264.25€366.95

Gréisst : 395nm

Quantitéit :

Rapport

Verletzung vum Copyright enthalenGratis Standardverschécken. Gesinn Detailer

Geschätzt tëscht Wed, Nov 5 an Mon, Nov 10

Dir kënnt de Produit bannent 30 Deeg no der Rezeptioun zréckginn. Gesinn Detailer

Shop mat Vertrauen

Suen zréck Garantie

Kritt den Artikel deen Dir bestallt hutt oder Är Suen zréck. Léier méi

About this item

Seller assumes all responsibility for this listing.Artikelnummer: 26392022

Item specifics

Item description from the seller

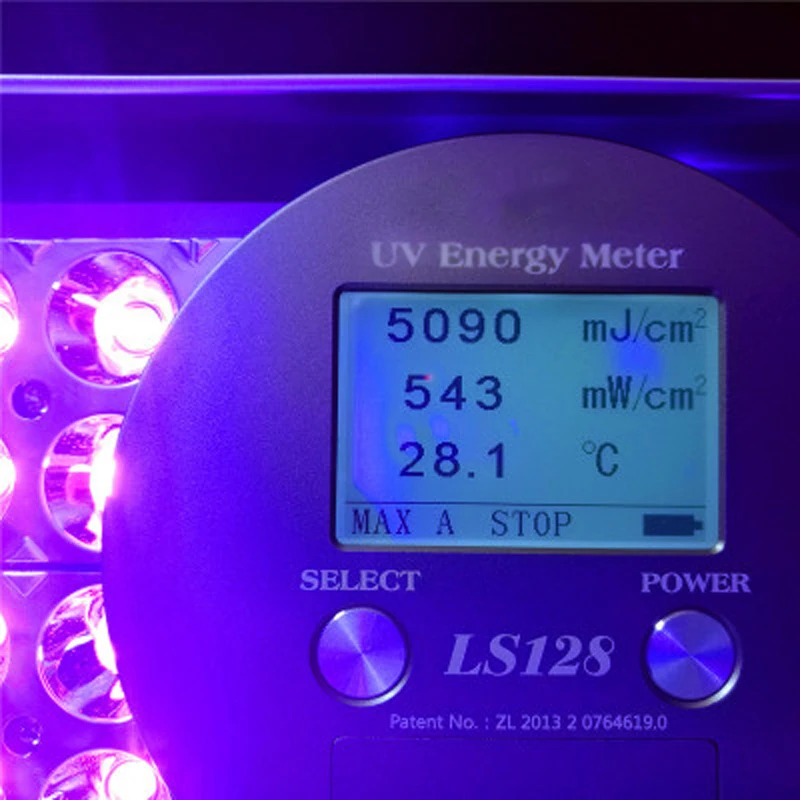

Light source type: Imported UV LED chip (wavelength 395NM/410NM/365NM).

Features: It is suitable for rapid curing of various UV shadowless adhesives. It has many features such as fast curing speed, strong penetrating power, no heat, low light decay, long life, low power consumption and so on.

Product advantages: LED light source has obvious advantages compared with traditional fluorescent tube/mercury lamp:

1, long life: the service life is more than 10 times that of the traditional lamp machine.

2, cold light source, no heat radiation, the surface temperature of the illuminated product is low, solving the traditional heat injury problem. Particularly suitable for LCD edge sealing, film printing, etc.

3, the heat is small, can solve the problem of large heat generation of traditional equipment.

4, instant lighting, no need to preheat to instantly achieve 100% power UV output.

5. The service life is not affected by the number of opening and closing.

6, high energy, stable light output, uniform illumination effect, improve production efficiency.

7. It does not contain mercury and does not produce ozone. It is a safer and more environmentally friendly alternative to traditional light source technology.

8, low energy consumption, power consumption is only 10% of the traditional lamp type, can save 90% of electricity.

9. Maintenance costs are almost zero.

Operation Tip: LED UV lamp should be as close as possible to the surface of the cured object. The closer the distance, the better. It should be kept within 3-10 cm. The irradiation distance will affect the curing effect.

4.4 aus 5 baséiert op 7,646 Rezensiounen

4.4 aus 5 baséiert op 7,646 Rezensiounen